Waste Steam to Power Generation

Harnessing waste steam to generate power represents a significant stride towards sustainable energy practices. Industrial processes often produce large amounts of waste steam that, if not utilized, results in energy loss. By converting this waste steam into electrical power, industries can significantly enhance their energy efficiency and reduce environmental impact.

How It Works

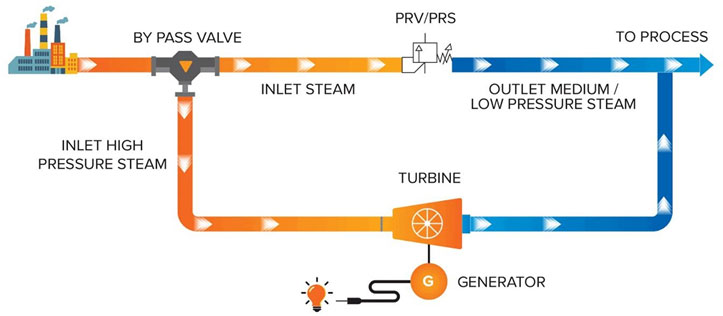

The process involves capturing waste steam typically released during manufacturing or power generation. This steam is then directed through turbines where its thermal energy is converted into mechanical energy. As the turbine spins, it drives a generator which, in turn, produces electricity. This method not only recovers lost energy but also decreases the reliance on fossil fuels.

Benefits

- Energy Efficiency: Maximizes the use of generated steam by converting waste into power, thereby optimizing energy consumption.

- Cost Reduction: Reduces energy costs by decreasing the need for additional power generation, leading to significant savings.

- Environmental Impact: Lowers carbon emissions by making the process more sustainable and reducing the overall carbon footprint of industrial operations.

- Sustainability: Enhances the sustainability of industrial processes by promoting the reuse of waste products.

This system converts waste Pressure from steam into clean electricity.

High Pressure (HP) Steam is diverted from the PRV(Pressure Reducing Valve) Inlet to the system, where useful energy available in steam can be converted into clean electricity and the low pressure steam will be available downstream for the process requirements. Ensures no interruption in existing plant process, Plant will get its desired steam temperature and pressure.

Application

- Chemical Manufacturing: Where steam is a by-product of many chemical reactions.

- Pulp and Paper Mills: Where steam is used in the drying process of paper.

- Metal Manufacturing: Where steam is used in the drying process of paper.

- Food and Beverage Industry: Where steam is used for processing and pasteurization.

Adopting waste steam to power generation not only makes industrial processes more efficient but also aligns with global efforts towards sustainability and reduced environmental degradation. It presents an opportunity for industries to turn waste into a valuable resource, ensuring energy security and operational efficiency.